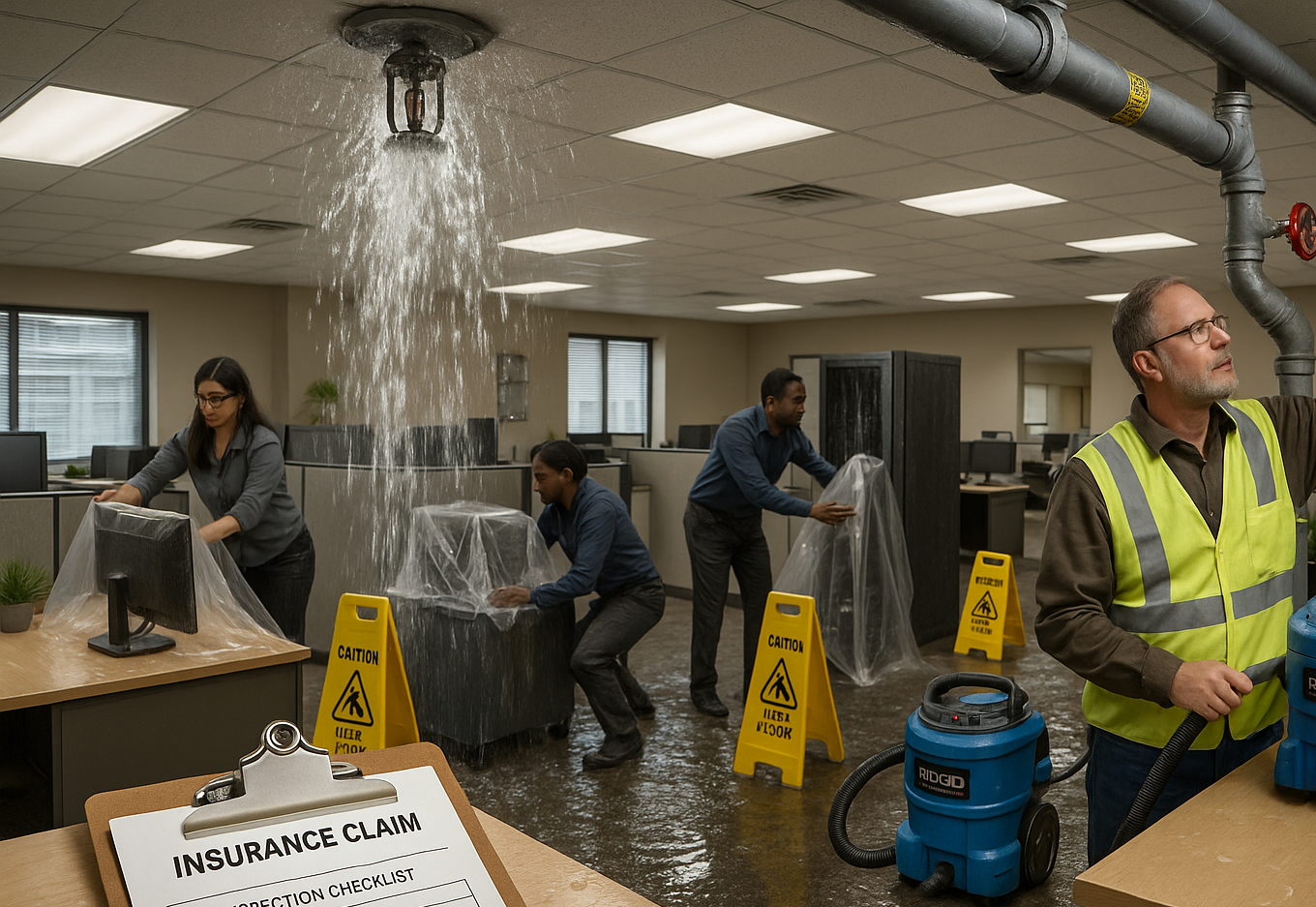

Accidental sprinkler discharge creates chaos fast. Ceilings drip. Floors flood. Computers soak. The goal is simple. Stop the water. Protect people. Start drying in hours, not days. This guide explains why sprinklers go off without a fire, how to reduce the risk in the first place, and what to do right now to limit water damage and downtime across Austin and Central Texas. You will also find cleanup steps, electronics care, and insurance tips that speed up claims. If you need immediate help, our team is on call day and night with rapid extraction across Austin, Round Rock, Cedar Park, Georgetown, and San Marcos.

24 by 7 Emergency Water Extraction in Austin. Call (512) 326 2633.

Do sprinklers go off by accident

True defects are rare. Industry data pegs historical defect activation odds at roughly one in sixteen million sprinkler heads per year. That means most unwanted discharges have a logical cause that you can prevent. Common triggers include exposure to heat sources, freezing or pipe bursts, accidental impact, corrosion, or tampering. Heat activates sprinklers, not smoke. Heads placed near skylights, heaters, cooking lines, or hot industrial equipment can reach activation temperature during normal operation. Choose the correct temperature rating for the environment per NFPA 13 guidance and locate heads away from steady heat to reduce nuisance activations. A simple head guard can stop a forklift mast, a ladder, or a flying ball from shattering a glass bulb or triggering a fusible link. Even a blast of canned air at close range can supercool a glass bulb and crack it, which is why safe cleaning practices matter.

References for reliability and causes support these facts. See industry overviews on sprinkler reliability and rare defect rates on ProQuest and Buildings. For top causes such as heat near heads, freezing, and impact, review the summaries and NFPA 13 excerpts on the QRFS blog. ECRI has also cautioned healthcare facilities on compressed gas blowing across bulbs. These resources all point to the same conclusion. Defect is the exception. Environment and maintenance drive the risk profile.

Prevent unwanted discharge

Small adjustments in design, hardware, and maintenance cut your risk significantly. The list below blends code guidance with field lessons from offices, schools, hospitality, healthcare, data centers, and high bay warehouses in Central Texas. The point is prevention. Spend minutes today to save hours of cleanup later.

Use listed head guards in risk areas

Guards or cages protect heads where mechanical injury is possible. Think loading docks, gyms, hotel corridors with luggage traffic, storage rooms, or anywhere a forklift, ladder, or ball might hit. NFPA 13 requires listed guards where heads are subject to damage. Guards must not obstruct the discharge pattern. Keep the 18 inch clearance below the deflector clear of stock. Do not paint or modify heads or escutcheons. Hospital inspection reports are full of citations for painted or loaded heads, which can cause failure or delay activation. Heavy duty guards sometimes need approval from the Authority Having Jurisdiction. Use listed products and follow manufacturer instructions. For a plain language review of guard rules and best practices, the QRFS guide on head guards is helpful, along with case examples in publicly accessible hospital inspection findings.

Choose correct temperature ratings and placement

Heat triggers heads. Smoke does not. Heads installed near hot process equipment, skylights with solar gain, unit heaters, or cooking lines must have temperature ratings that match the expected ambient conditions. NFPA 13 tables guide this choice. Avoid direct line of heat at the deflector. Add baffles or adjust spacing when local heat sources are present. Catch the early signs of heat related issues such as slight weeping, recurring ceiling tile staining near a head, or discolored bulbs from overheating. If you are unsure about ratings in a specific room, ask your sprinkler contractor to verify selections against NFPA 13 criteria, especially during tenant finish or remodels that introduce new heat sources.

Freeze protection for Central Texas

Central Texas rarely sees long hard freezes, yet short bursts still break pipes and heads. Maintain at least 40 degrees Fahrenheit in all wet sprinkler areas. Insulate piping in exterior walls, attics, or unconditioned spaces. If you cannot maintain heat, consider dry or preaction systems for those zones. For systems that use antifreeze, the rules changed on September 30, 2022. Legacy mixes sunset on that date. New or replacement antifreeze must be a listed solution that meets UL 2901. Test antifreeze annually per NFPA 25 to confirm concentration and freeze point. The National Fire Sprinkler Association has updates on listed antifreeze and testing frequency. These steps reduce freeze risk in attics, breezeways, garages, and stairwells common to Central Texas multifamily and campus buildings.

Inspection, testing, and valve supervision

NFPA 25 places inspection, testing, and maintenance on the owner. That includes keeping control valves in the correct position, locked or electrically supervised. A supervised valve can reduce the weekly inspection cadence, which cuts human error. Train your staff on the location of risers, inspectors test valves, and main controls. Keep an impairment plan on file, with contacts for your sprinkler contractor and the fire department. The QRFS overview on control valves versus head level shutoff tools explains why a local shutoff at the head often beats a full system shutdown. You avoid a full impairment while you address the damaged head. When you do close a main valve, post a fire watch, notify your monitoring service, and restore protection as fast as possible.

Corrosion and obstruction control

Corrosion and debris cause leaks and unexpected failures. Microbiologically influenced corrosion, mineral scale, and foreign material can block or weaken piping. Dry systems are more susceptible, which is why many owners use nitrogen to limit oxygen in those pipes. NFSA has guidance on obstruction investigations and corrosion mitigation. For wet systems in older buildings, periodic internal inspections catch tuberculation and sludge before it becomes a leak or reduces flow. Watch for pinhole leaks, black water discharge from drains, or visible rust at hangers as clues. When in doubt, have your contractor pull sample sections for internal review.

Use preaction in water sensitive spaces

Server rooms, museums, medical imaging suites, and operating rooms have very low tolerance for accidental water release. Preaction systems add a confirmation step so water enters piping only after a detection event, then a second event opens individual heads. This reduces the chance of a single point impact or minor heat source dumping water on mission critical assets. NFSA overviews preaction and other system types. Preaction is not a cure all. It still needs maintenance, supervision, and testing. For many owners in Austin with mixed office and tech suites, preaction in the data room plus standard wet coverage elsewhere strikes the right balance.

What to do right now

Water spreads in minutes. A calm checklist helps. Keep people safe. Stop the flow. Start the drying clock. Then document everything for insurance. If there is any sign of fire, call 911 first. If you ever feel unsafe, call the fire department for help with shutoff and scene control.

Safety first

Watch for electrical hazards. If outlets, power strips, or equipment are wet or submerged, shut power off at the main only from a dry location. The CDC warns against energizing wet systems or using power near pooled water. Do not re energize until a licensed electrician inspects the system. Protect your team from slip and fall hazards. Set up a simple perimeter with caution tape or cones. Look for ceiling sag or bowing drywall from trapped water. Keep clear until a pro relieves the load.

Stop the water

If there is no fire, a shutoff tool used on the flowing head can stop the discharge in seconds. Tools like Shutgun or Quickstop clamp over the head to block flow. This method contains damage without removing fire protection from the rest of the building. If you do not have a tool, locate the sprinkler riser and control valve for that area. Close the valve per your emergency plan only if it is safe. A closed main creates a system impairment. Post a fire watch. Notify your alarm company. Restore protection as soon as the damaged head is replaced. The QRFS guide on shutoff tools versus control valves shows how head level shutoff reduces risk during the first minutes after an activation. Firefighternation also notes that stopping flow fast protects the building and speeds return to service.

Start cleanup within 24 to 48 hours

Microbial growth can begin within one to two days. The EPA recommends starting drying within that window to reduce mold risk. Category 1 water from a wet sprinkler system is relatively clean at first. It can deteriorate to Category 2 or 3 as time passes or as it picks up soil and building debris. The IICRC S500 standard explains this progression and sets methods based on water category, the size of the loss, and the porosity of materials. Quick extraction, controlled demolition where needed, dehumidification, and consistent airflow reduce damage and shorten the project.

Protect electronics and data

Do not power on wet equipment. Unplug from a dry location. Remove batteries if possible. Move devices to a dry area with airflow and desiccants. The CDC and the International Association of Electrical Inspectors both caution against energizing damp electrical systems or equipment. High value electronics such as servers, imaging systems, and telecom gear should be evaluated by a qualified vendor before power returns. Document serial numbers and condition for your claim file. Many commercial policies include coverage for wet electronics, including data restoration in some forms.

Need help right now? Call our local team for rapid extraction, containment, and drying. We handle moisture mapping and daily monitoring. We also document every step for your carrier. Read about our core service at water damage restoration.

Cleanup steps that work

Every building is different. The science is consistent. Remove water quickly. Set the right drying goals. Choose the correct approach for each material. Track progress with moisture readings and psychrometrics. The sections below explain how a pro team approaches these tasks in offices, schools, healthcare suites, and homes.

Extract standing water and set containment

Begin with safety. Switch off affected circuits from a dry location. Once safe, extract bulk water with truck mounted or portable units. Pull water from carpet and pad or hard surfaces until you reach minimal residual moisture. Set up containment to protect unaffected areas. Use poly walls or zip walls to separate dry spaces from wet zones. Install floor protection along traffic routes to protect clean areas. Remove cove base or toe kicks to release trapped water. Open drop ceilings where water trapped above creates sag or stain. Bag debris as you go to reduce cross contamination.

Moisture mapping and drying targets

Moisture mapping creates a precise plan. Use meters to measure moisture content in drywall, base plates, cabinets, and hardwood. Thermal imaging helps find hidden wet spots, though a meter confirms readings. Set drying targets based on unaffected materials in the same building. Then size dehumidification and air movement to hit those targets. Desiccant dehumidifiers help in cool conditions or large commercial spaces. LGR units handle most residential and small commercial jobs in Austin. Track grains per pound, relative humidity, and temperature every day to confirm progress. Adjust equipment and containment as the job progresses.

Decisions by material

Carpet and pad can often be saved with rapid extraction and drying. The exception would be contaminated water or delamination. Glue down carpet can trap water under the adhesive, so check edges and transitions with a meter. Drywall with limited wetness often dries in place with base removal and airflow. Heavily saturated drywall with visible swelling will likely need flood cuts. Cabinets with particle board bottoms usually swell and require removal. Solid wood boxes sometimes dry in place with back removal and targeted airflow. Hardwood floors demand a quick response. Mat systems and panel systems can pull moisture from tongues and grooves. Severe cupping or crowning may still require removal. Concrete slabs in offices and schools hold a lot of moisture. Run dehumidification longer to reach equilibrium and avoid adhesive failures on new flooring.

Odor and contamination control

Category drives cleaning choices. Clean sprinkler water at the start calls for standard antimicrobial application on wetted surfaces after extraction. If the water sat for days or picked up debris, treat it as a higher category. That may require more aggressive demolition and disinfection. HEPA air filtration helps control aerosols during demolition. Do not spray over wet gypsum or panels without first addressing source water and removing wet material. The IICRC S500 details methods for each category and class. A trained tech will classify the loss and document the plan.

Insurance tips that pay off

Most homeowners policies list accidental discharge or overflow of water or steam from plumbing, HVAC, or automatic fire protective sprinkler systems as a covered peril. Flood is a separate coverage. Commercial property forms include sprinkler leakage coverage for similar events. That means most accidental sprinkler discharges are covered claims for buildings and contents. Filing a clean claim with good documentation speeds payment. The steps below help.

What policies usually cover

Residential carriers cover building and contents damaged by accidental sprinkler water. Additional living expense may apply if your home is temporarily uninhabitable. Commercial policies often cover building damage, contents, and in many cases business interruption, subject to form and waiting periods. The Insurance Information Institute provides a good overview of perils such as accidental discharge or overflow. IRMI defines sprinkler leakage coverage as it applies to commercial property forms. For Austin homeowners with questions, our guide on does homeowners insurance cover restoration offers local context.

Documentation checklist

Document during the first hour where possible. Take wide photos of each room then close ups of damage. Capture serial numbers on electronics, appliances, and gear. Save purchase receipts when available. Keep a simple loss inventory by room. Record any emergency steps you take such as shutoff, extraction, or tarping. Keep all third party invoices. The National Association of Insurance Commissioners gives practical advice on photos, receipts, and item lists when filing claims. Share your documentation with the adjuster before the first site visit to speed approval.

Working with adjusters

Set expectations with your assigned adjuster early. Share the moisture map, psychrometric logs, equipment counts, and daily progress updates. Agree on any demolition scope before removal when possible. Ask about caps on dehumidifier days or category driven cleaning limits. If you run a business, ask about business interruption coverage and waiting period details. We can assist with carrier communications and scope writing. Many carriers in Texas use us as a preferred vendor for water and fire losses. If cost is a concern before filing, read our breakdown of the cost of water damage restoration in Austin to get a sense of pricing ranges.

When to upgrade the system

Sometimes a targeted upgrade reduces risk in the most sensitive spaces. Preaction in a server room isolates water until sensors confirm a real event. Nitrogen generators on dry systems limit corrosion and reduce ice formation. Clear signage near valves and risers speeds shutoff during an emergency. Head guards in gyms, playrooms, hotel corridors, and loading areas stop common impacts. For multifamily, consider listed antifreeze in breezeways or garages exposed to cold snaps. Small changes in a few rooms can prevent a flood across a floor. For mixed fire and water incidents where smoke and soot are present along with water, our team also handles fire damage restoration to return spaces to pre loss condition.

How to stop a discharge

The fastest action wins. Keep people safe. Then halt the water. Then dry. The steps below mirror the HowTo schema structure for clarity.

- Protect yourself. Stay clear of energized gear or wet outlets. Shut power off from a dry location if circuits are threatened. Wear gloves and eye protection. The CDC offers clear electrical safety guidance for wet conditions.

- Stop the water. If no fire is present, apply a sprinkler shutoff tool to the flowing head. This keeps the rest of the system live. If you lack a tool, locate the riser and close the control valve for that zone if safe, or ask the fire department to assist. QRFS explains how head level tools work and why they avoid a prolonged impairment.

- Call a pro. Contact our team for rapid extraction, drying, and documentation. Start a claim and tell your carrier you have engaged a certified firm for mitigation. Learn more about our process on water damage restoration.

- Protect electronics. Unplug from a dry spot. Do not power on wet devices. Remove batteries where possible. Set devices aside for vendor evaluation. The CDC also warns against energizing damp equipment.

- Document and dry. Take photos and video before moving items if it is safe. Log serial numbers. Start drying within 24 to 48 hours as the EPA recommends to reduce mold risk.

Quick facts

These short points answer the most common questions our Austin clients ask after an accidental sprinkler event. Each one links to a reputable source for deeper reading.

- True defect activation odds run about one in sixteen million heads per year, historically. Source: ProQuest and Buildings industry summaries.

- Most unwanted activations trace to heat exposure, freezing, or impact. Correct temperature ratings and listed guards prevent many events. Source: QRFS on top causes.

- Start drying within 24 to 48 hours to lower mold risk. Source: EPA flooded home guidance.

- Homeowner policies usually cover accidental discharge or overflow from automatic fire protective sprinkler systems. Flood is separate. Source: Insurance Information Institute.

FAQs

What causes an accidental fire sprinkler discharge?

Most events come from predictable triggers. Heat near a head. Freezing that cracks piping. Mechanical impact from a ladder, lift, or ball. Corrosion or debris that weakens components. Tampering. Actual manufacturing defects are extremely rare. Heat without flame is still heat to a sprinkler. Use the right temperature rating and avoid heat sources nearby. See QRFS for an overview of causes and NFPA 13 placement guidance. Read industry reliability research on ProQuest for context on defect rarity.

How do I stop a sprinkler that went off?

If there is no fire, apply a sprinkler shutoff tool to the flowing head. This method stops the water fast without shutting off the entire system. If a tool is not available, locate the control valve for that zone and close it only if it is safe. Post a fire watch. Notify monitoring. Call a licensed contractor to replace the head and return the system to service. The QRFS guide explains the pros and cons of each method in plain terms.

Will insurance cover sprinkler water damage?

Most homeowners policies cover accidental discharge or overflow from an automatic fire protective sprinkler system. Commercial policies include sprinkler leakage coverage. Document everything. File promptly. Keep receipts. Flood coverage is separate. The Insurance Information Institute and IRMI provide definitions and examples. For a local walkthrough, read our post on does homeowners insurance cover restoration.

How fast can mold start after sprinkler water?

Microbial growth can begin within 24 to 48 hours. That is why extraction and dehumidification should start immediately. The EPA provides clear guidance on drying timelines and protective steps during cleanup.

Should I use guards on sprinkler heads?

Yes in areas where heads can be hit. NFPA 13 requires listed guards where heads face mechanical injury. Do not block discharge patterns. Keep the 18 inch clearance below the head. Do not paint or alter heads. QRFS provides a helpful guide on guard selection and color rules.

Why Austin Hi Tech Restoration?

Local response matters during the first hour. Our crew is based in Austin. We have helped more than eighteen thousand local families and businesses since 1991. We hold an A plus rating with the Better Business Bureau. We are a preferred vendor for seven of the top eight Texas carriers. We respond within hours across Austin, Round Rock, Cedar Park, Georgetown, and San Marcos. We coordinate with adjusters daily. We document with photos, moisture maps, daily psychrometric logs, and a room by room scope. That level of documentation speeds approvals and reduces stress.

Learn more about Austin Hi Tech Restoration or visit our home page to see our services for water and fire restoration in Austin since 1991. We also practice greener drying methods where practical. Read our article on eco friendly water damage recovery to see how we reduce waste and save energy while still hitting drying goals.

Primary CTA 24 by 7 Emergency Water Extraction in Austin. Call (512) 326 2633. Secondary support for claims is available. We help with photos, measurements, and fast drying to prevent mold.

Austin specific tips

Central Texas brings unique sprinkler risks. Winter cold snaps are short yet severe. Protect risers and attic mains with heat trace or insulation where practical. Breezeways and garages in multifamily buildings need special attention. Roof mounted HVAC can drip condensate onto heads below skylights, which raises humidity and affects finishes. Summer heat under dark roofs can push attic temps near activation thresholds. Use the right temperature ratings in these zones. Open office remodels often add pendant lights or heaters. Have your sprinkler contractor confirm clearance and heat effects before final install. Schools and gyms need listed head guards near courts and stages. Hotels should install guards in corridors with luggage cart traffic and low ceilings. Healthcare suites should look at preaction in imaging and operating areas where water exposure has high cost.

Electronics triage in plain steps

Electronics fail from water and from the decision to power up too soon. Follow this simple plan for computers, servers, and medical devices after a sprinkler event.

- Unplug from a dry location. Do not touch a wet plug or outlet.

- Remove batteries where possible. Do not press power.

- Move to a dry room with airflow. Use fans and desiccants to lower moisture.

- Do not use heat guns on circuit boards. Gentle air only.

- Call the vendor for a cleaning and inspection plan. Many offer post incident service.

- Document serial numbers and visible condition for your claim file.

The CDC warns against energizing damp electrical systems. IAEI provides guidance on water damaged electrical equipment. For servers and storage arrays, bring in a data recovery partner if drives were exposed. Fast action preserves options.

What to avoid

Never paint a sprinkler head to hide staining. Paint can delay or prevent activation during a fire. Do not hang items from heads or piping. The weight can damage threads or change spray patterns. Do not clean bulbs with compressed canned air at close range. Rapid cooling can crack the bulb and release water. Do not close a main valve without a plan for fire watch and system restoration. Never re energize circuits that were wet without an inspection. Do not delay drying beyond the first day or two. Delay raises category and cost.

Local help and next steps

If you are reading this during an active release, take these steps now. Confirm no fire. Shut off power from a dry location if water reached outlets. Use a shutoff tool if available. Call us for rapid extraction. Start photos and video. Move sensitive items to a dry room. We arrive with extraction units, dehumidifiers, air movers, moisture meters, and containment materials. We work with your adjuster while you focus on your team or family.

For scheduled projects and prevention planning, we can walk your building and flag risk areas. This includes guard recommendations, heat source clearance checks, and freeze exposure notes. For water sensitive spaces, we can coordinate with your fire protection contractor on preaction or dry system plans.

Contact Austin Hi Tech Restoration to schedule a walkthrough or request emergency service right now.

If smoke or fire damage is present along with sprinkler water, our team manages both scopes to reduce delays. Visit our page on fire damage restoration for details on deodorization, soot removal methods, and build back sequencing.

Sprinklers save lives. A rare unintended discharge should not become a months long repair. Prevention keeps the odds low. Rapid action cuts the loss when it happens. Start with safe shutoff. Dry fast. Protect electronics. Document for your carrier. Our Austin team stands ready to help at any hour.